CrystalView Microscope Overview

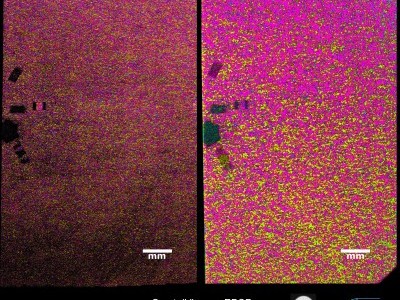

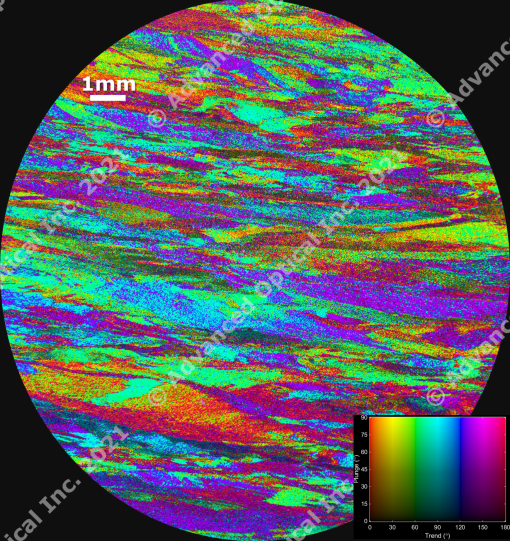

CrystalView is the only patented laser polarized-light microscope (PLM) developed for quantitative large-area microstructure characterization with an instant field-of-view exceeding 2cm2. CrystalView is the first and only Quantitative Wide-Field PLM, offering the fastest imaging - 15 minutes including processing - and higher contrast than electron backscatter diffraction (EBSD) without pixel replacement. Microscopy Today recognized CrystalView as a top ten 2024 Innovation Award winner.

CrystalView’s fundamentally new design significantly outperforms computational add-on PLMs in terms of field-of-view, speed, material diversity, and surface tolerance, and its unique horizontal configuration allows crystallographic imaging of large and in-situ parts. CrystalView consolidates optical and orientation imaging, expanding microstructure visualization and analysis. CrystalView is the only true high-throughput crystallographic microscope for material research and production facilities.

Benefits

CrystalView is a fast and affordable microscope that allows users to analyze microstructures over larger areas for improved statistics

Measure Non-Destructively

Visualize crystallographic microstructure without cutting your parts

Expand Field-of-View

Collect crystallographic orientation images 1" x 1" and larger

Simplify Sample Preparation

CrystalView works for rotary polished samples and suffers fewer non-indexed pixels than EBSD

Reduce Cost

Dramatically reduce sample preparation and labor costs

Return on Investment (ROI)

| Time Saved Per Sample | Savings Per Year | Productivity Gains |

|---|---|---|

| 30 to 45 hrs | Over $1.5M (For 2000 samples) | ~300% |

Applications

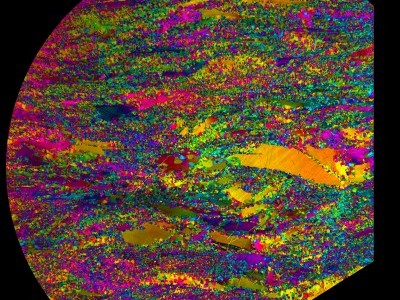

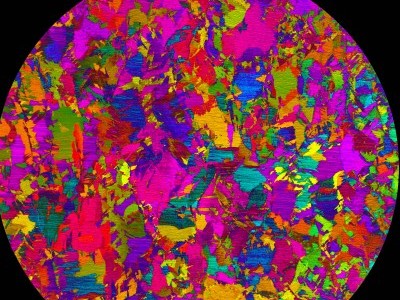

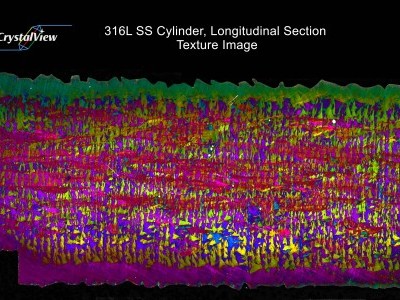

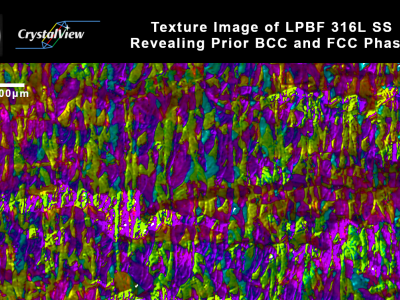

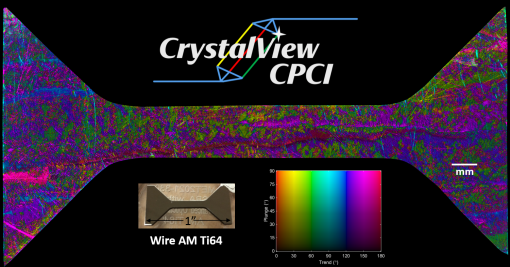

The CrystalView microscope offers non-destructive, large-area, high speed orientation imaging for grain-boundary & microtexture analysis, process development, quality control, failure analysis, and other applications with non-cubic and cubic metals including titanium, zirconium, nickel, stainless steel, aluminum and most of their alloys. Systems can also be customized for oriented non-metals including ceramics, fiber composites, textiles, and plastics.

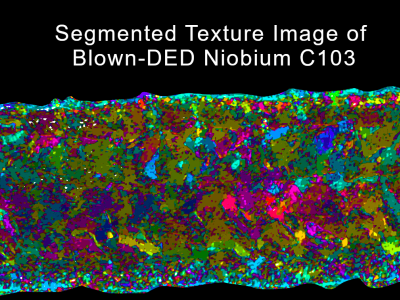

CrystalView allows visualization of material microstructural properties correlated with failure and corrosion probabilities in high-strength and high-performance parts for additive manufacturing, aerospace, automotive, chemical, defense, energy, architectural, and medical applications. CrystalView works in air and, as a parallel imaging technique, at much higher speeds and fields-of-view than scanning alternatives.

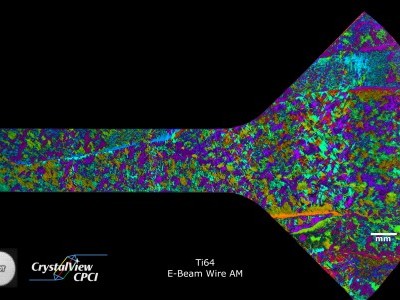

Crystallographic Non-Destructive Testing Additive Manufacturing

Sandia Lab News: Titanium Imaging Advances

Sandia materials scientist Joseph Michael was paired with AOT for the project and conducted a test using a scanning-electron microscope, current technology that can be difficult for small businesses to access because the microscopes are large, expensive and require experts to run. "Metals characterization is one of Sandia's strengths -- we have been doing this for many years," Michael said. "It's been energizing to me to see other techniques that can do some of the things that we do in the lab in a faster, higher-throughput way," he said. "It's been exciting to see it all happen. If you can generate data that gets you 90% of the solution and do it quickly from an unprepared sample, that's a great place to be."

This excerpt is from Sandia National Laboratories's website regarding

CrystalView CPCI - Read the full article here.

True High-Throughput Crystallography

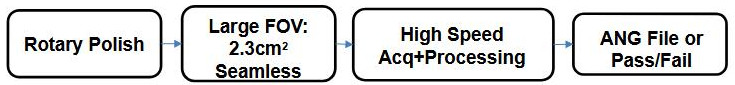

CrystalView Process for 2.3cm2 Image Size

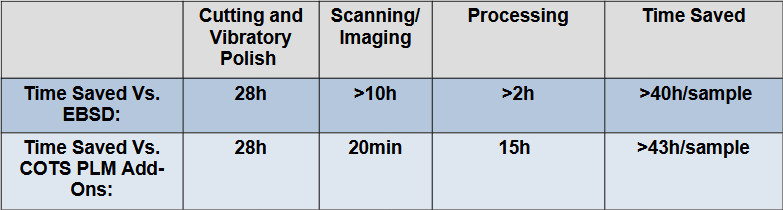

Time Saved with CrystalView

CrystalView offers the fastest imaging - 15 minutes including processing - over 2.3 cm2 instant field-of-view, without cutting the part. It can image rotary-polished samples, saving 24 hours or more of polishing time. Alternative COTS PLM add-ons may offer high instrument throughput, but are slow to process images due to curve-fitting. CrystalView employs closed-form mapping rather than curve-fitting, making it the only true high-throughput crystallographic microscope for material research and production facilities.

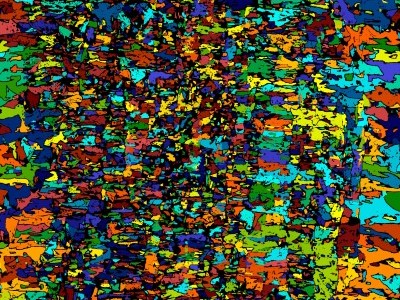

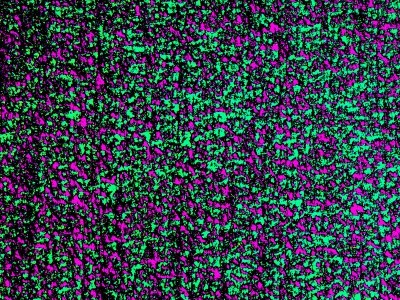

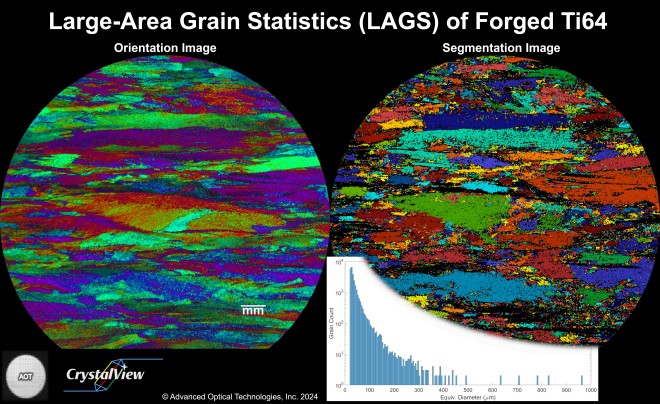

Large-Area Grain Statistics (LAGS)

CrystalView Large-Area Grain Statistics (LAGS) provides maximum confidence in crystallographic analysis. The image below demonstrates LAGS of forged Ti64 encompassing over 10,000 grains. The segmentation image was generated, consistent with ASTM E2627, in under 30 minutes on a standard laptop computer.

Related Publications

Quantitative Large-Area Polarized-Light Microscopy

Electrodynamic Solution for Polarized Reflectivity and Wide-Field Orientation Imaging of Uniaxial Metals

Polarized Reflectivity for Quantitative Crystallography of Alpha-Titanium

How can AOT help you?

Send us a message and we will get back to you within two business days.