Applications

Home / Applications

Patented solutions from Advanced Optical Technologies provide unique remote-sensing capabilities for material mapping and ISR (Intelligence, Surveillance, and Reconnaissance), and in material characterization for orientation imaging and non-destructive testing. AOT also provides comprehensive, unparalleled, and affordable polarization calibration of optical components for space and defense sensors and optical signature measurements with unparalleled accuracy and adaptability. Sensors and measurements can be customized to your application.

Material Mapping & Assessment

AOT machine-learning algorithms improve the performance of electro-optical sensors for material mapping and can be implemented in either microscope or telescope formats, ranges, and resolutions. Field sensors can be configured for space, defense, security, and environmental applications at high speed and long range according to material type. Sensors and algorithms sensitive to material stress or damage can be utilized for manufacturing product inspection and quality control.

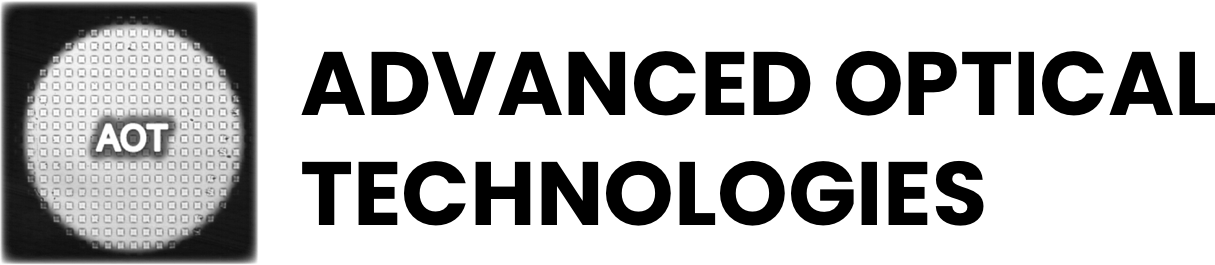

Crystallographic Non Destructive Testing

AOT's CrystalView CPCI ushers in a new era of non-destructive testing, allowing visualization of microstructural properties critical to high-strength and high-performance aerospace, energy, architectural, and medical parts and materials. CrystalView CPCI is a parallel imaging technique that works in air at much higher speeds and fields-of-view than scanning alternatives.

Optics Calibration & Certification

Building an effective optical sensor or device requires high-accuracy calibration of its optical components, often beyond the level of detail available in vendor datasheets. Accurate comprehensive specifications such as the component Mueller matrix or scattering matrix can be digitized for use in compatible computer-aided design (CAD) programs and models. Calibrate your optics to AOT's standard and avoid time-consuming diagnostics, design rework and budget overruns.

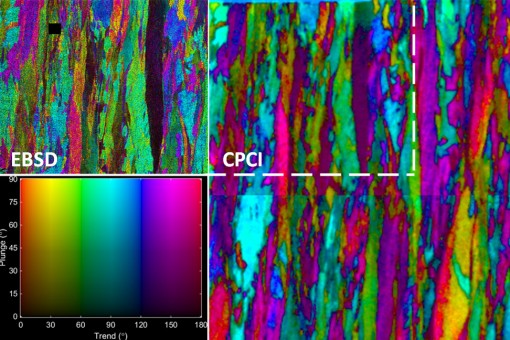

Additive Manufacturing

CrystalView CPCI applies to additive manufacturing for process qualification and control of 3D-printed metal parts through microstructure characterization. AOT reflectance modeling also applies to characterization of AM surfaces, either post-build or layer-wise. Through crystallographic and surface characterization AOT sensors can accelerate development and acceptance of AM processes.

Space

AOT measurements and sensors support space enterprise from advanced telescopes to classification algorithms and simulations to material characterization. We support telescope design and retrofitting for polarization data and empower classifiers for material-based tracking, assessment, and anomaly/change detection from resolved or unresolved imagery. AOT reflectance models and metrology support image analysis and rendering while AFM imaging elucidates space aging and related material properties.

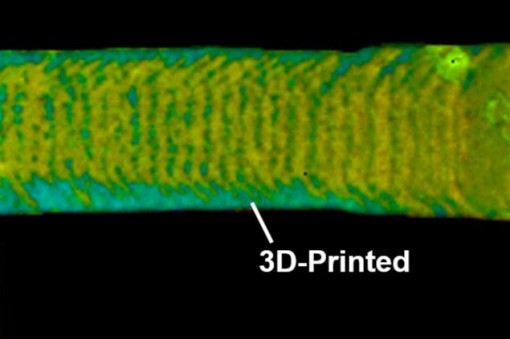

Defense & Security

AOT's material-mapping algorithms provide unique advantages for tactical surveillance, ATR, asset tracking, search & rescue, and diverse intelligence, surveillance, and reconnaissance (ISR) applications, all at video rates as required. Defense & security sensors can operate in low-cost compact passive mode, high-specificity robust active mode, or hybrid active-passive mode, all in various bands including eye-safe short-wave infrared(SWIR).

How can AOT help you?

Send us a message and we will get back to you within two business days.