Optics Calibration & Certification

Home / Applications / Optics Calibration & Certification

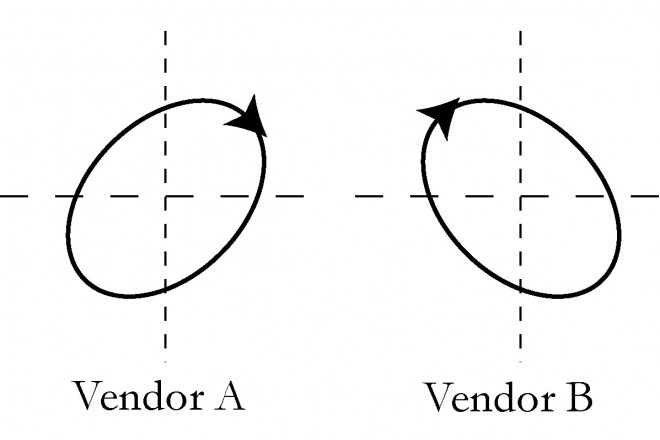

Achieving accurate control and measurements of optical scattering and polarization is a challenge documented in a large body of metrology literature. Actual scatter distributions are usually more complex than the predictions of simple parameter models, especially in their dependence on microstructure, wavelength, polarization, and other variables. Commercial polarization optics can vary by 5-10% from theoretical truths, introducing errors too large for demanding polarization devices and sensors. Part of this challenge stems from under-specification of the optical components (waveplates, polarizers, etc.) needed to make polarization measurements, which can be overcome by measuring and calibrating the full polarization signature, or Mueller matrix, of components with a sufficiently accurate Mueller-matrix polarimeter. AOT's calibration service can help you achieve the accuracy you need in your polarization device or sensor. Diffuse polarized reflectance can be measured to build accurate databases.

Dr. Goodman Explains the Need for Certified Polarization Optics (click for video)

Tower Optical Blog: AOT Qualifies Waveplates

Laser polarimeters, which in their most general form are also known as Mueller-matrix polarimeters, measure the linear response of materials and objects to polarized light. They are increasingly applied in the defense, aerospace, semiconductor, and manufacturing sectors for object and material recognition, non-destructive testing, and characterization, both in imaging and spot-scan formats. The primary advantage of a laser polarimeter, much like a multi-spectral sensor, is a high-dimensional material signature that can be obtained at high speeds and practical ranges and used to classify objects and materials with high specificity. Polarimeters classify a material according to its response to different polarization states, or oscillation patterns of the electromagnetic field, rather than different colors as in a multi-spectral or hyperspectral sensor.

Most laser polarimeters rely on birefringent crystal waveplates to modulate the polarization states of the probe and detected laser light. Accurate measurement of polarization signatures requires the waveplates to transform various input polarization states according to known formulae. In mathematical terms, the Mueller matrices of the polarimeter waveplates must be within a certain tolerance of the Mueller matrix of an ideal waveplate.

This excerpt is from Tower Optical's website - Read the full article here.

How can AOT help you?

Send us a message and we will get back to you within two business days.