Additive Manufacturing

Home / Applications / Additive Manufacturing

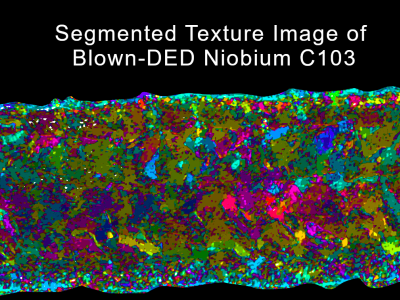

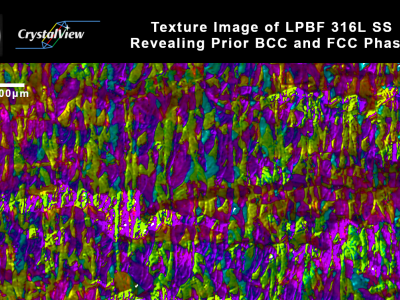

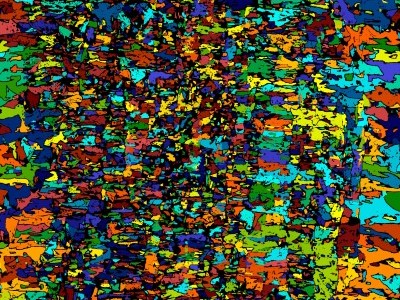

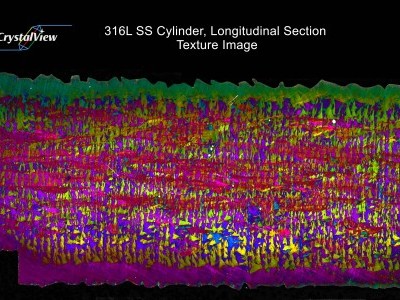

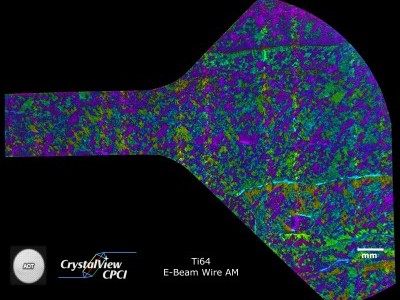

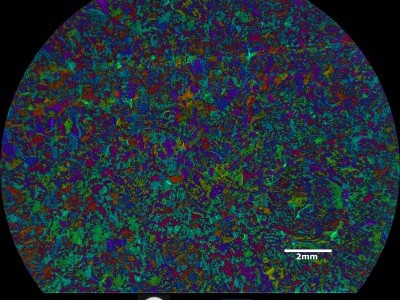

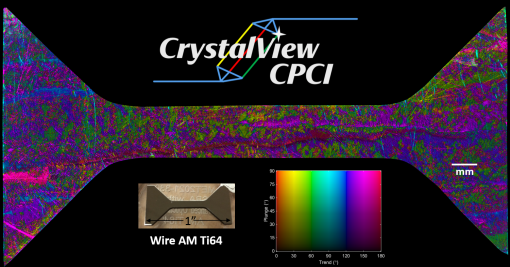

Additive manufacturing offers unique capabilities to control crystallographic structure in high-performance parts. Utilizing this capability to print parts with mechanical, electrical, or chemical properties superior to conventional counterparts requires affordable and non-destructive crystallographic imaging over large areas. AOT's CrystalView Microscope provides crystallographic orientation imaging at much greater speeds and image sizes than competing techniques and can accelerate development and acceptance of AM processes.

CrystalView Data Supports

- Grain Orientation Imaging, to determine the crystal orientation, size, and shape distribution of grains in materials.

- Phase Mapping, to distinguish different phases and prior-phases in a material, helping understand the microstructural evolution during processes like corrosion and heat treatment.

- Texture Analysis, to gain complete understanding of materials, including defects, failures, boundaries, stress, twins, etc., for predicting material properties or estimating the life of a component.

Benefits of the CrystalView Microscope

Return on Investment (ROI)

| Time Saved Per Sample | Savings Per Year | Productivity Gains |

|---|---|---|

| 30 to 45 hrs | Over $1.5M (For 2000 samples) | ~300% |

- Saves time in busy material labs, where internal and external customers might otherwise wait weeks or months to get data, missing their deadlines.

- Images more materials and saves time on sample preparation.

- Pays itself off in a year depending on the number of samples being measured.

- Consolidates multiple instruments in one microscope, providing conventional optical imaging, crystallographic imaging, and phase mapping (like EDS), with new modalities regularly added.

- Provides unique capabilities including crystallography of large industrial parts, transmissive and reflective samples, and in-situ deformation testing.

- Enables true high-throughput crystallographic analysis without destroying the part.

- Accommodates odd-shaped, bulky, and large 3D parts, making it a unique tool for additive manufacturing. Parts imaged can be put into service.

- Simplifies material characterization through turnkey operation, robust sample mounting, and optional remote control.

- Gains value while you sleep, with updated materials, models, and software features added regularly.

Testimonial

We used CrystalView to characterize microstructure of a Ti alloy. CrystalView successfully measured C-axis orientations in different locations of a 3” x 5” plate without the need for sample cutting. The comparison between CrystalView and EBSD results, including C-axis orientation and microstructure morphology, showed insignificant differences, while CrystalView speed was at least 20 times faster than EBSD. In addition, CrystalView exported data in an ANG file format which can be used in other software for quantitative analysis such as grain segmentation.

Dr. Vahid Tari

Senior Modeling Engineer at ATI Materials

Gallery

How can AOT help you?

Send us a message and we will get back to you within two business days.